Curing Nano470 Adhesive

Safe Light Technology

P.O Box 131 Varsity Lakes QLD 4227

Phone 1300 550 233 Fax 07 55 728081 Mobile 0412 427 822

Nano470 leads the way in revolutionary new light curable adhesives! In the past, bonding glass to glass or glass to metal has only been possible using UV light for curing adhesives. Now, Nano470 technology allows the curing process to occur using only a white fluorescent tube. Amazing!

The light source required for adhesive bonding is now less expensive, readily available in a range of different sizes/shapes and results in a simplified bonding process. As well, the final bonding result is as good, if not better than, any bonding that occurs using UV light.

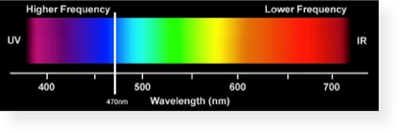

Pictured below, is the visual part of an electro magnetic spectrum which illustrates energy frequency. It is clear from this diagram, that 470 nanometers, the peak curing frequency of Nano470, is within the safe visual spectrum because it only uses white light for curing. Other adhesives that require UV light to cure are not visible on this part of the spectrum because they fall outside this safe range. Nano470 Adhesives can be cured using UV light if this is your preferred light source.

Nano470 Adhesives are, therefore, the safest and most convenient way to bond glass to glass or glass to metal without compromising the strength of the bonded structure

White Light / UV Curing

No UV Radiation Needed

All other glass adhesives in the Australia need UV Radiation to set (cure).

Nano470 only needs a white Fluorescent light. That is 100% Safe for you